98

|

design

mag

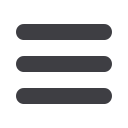

We spoke to a leading Perth builder about the use of

Austral Deck on an eight-storey apartment building as it

approached the end of its structural phase.Vibe

Apartments is located in Wellington Street, East Perth close

to the restaurant and cafe life of this newly-regenerated

inner suburb.

Once completed in early 2015,Vibe will have sixty

apartments, mostly one- and two-bedroom, including five

two-storey penthouses, as well a gym, pool, two levels of

parking (one below grade), and even a rooftop garden,

outdoor theatre and viewing deck.

Rodney Naef of Ren Construction is an old hand when it

comes to building in precast, both walling and flooring,

and his enthusiasm for the Austral Deck system is

undimmed.

“It’s quick,” he says,“very quick.” Rod describes as

“time-consuming” the preparation required for a

conventional in situ monolithic slab.“Basically, we’d be up

there for three weeks trying to deck it out.”

How does this compare with the Austral Deck? “With the

Austral system we ‘d be backpropping for a day, maybe a

day-and-a-half, and the next day you’ve got a whole level

covered!” Rod estimates that the Austral Deck system

halves the number of props required.According to Austral

Precast, an average of ten Austral deck planks covering

an area of 150 square metres can be installed per hour.

Rod adds that “You’ve got a nice, clean, safe working

deck straight away for everybody to start working on.”

So how quick is quick in the real world? “On this job we

have floorplates of about 900 square metres each and we

are doing a floor level basically every eleven working days.

So it goes in fast.”

Rod was caught by surprise when we asked about any

downsides with the Austral Deck system.“Do you know

what, I can’t tell you any, to be honest!” He says it’s a little

more costly on a material per square metre basis than a

conventional in situ slab but this is quickly recouped in

time and speed.“So I can’t really give a negative on the

system.”

As well as supplying 533 Austral Deck planks,Austral

Precast also manufactured 736 precast wall panels for this

project, 75 upstands and 28 precast stairs.“The stairs are

craned in off the truck, lowered straight in,” to the fire–rated

stairwells made from precast panels, of course,“and

there’s your access immediately,” he says with enthusiasm.

As we talked to Rod, the final level of the Vibe Apartments

project was being poured and the structural phase was

all but complete.

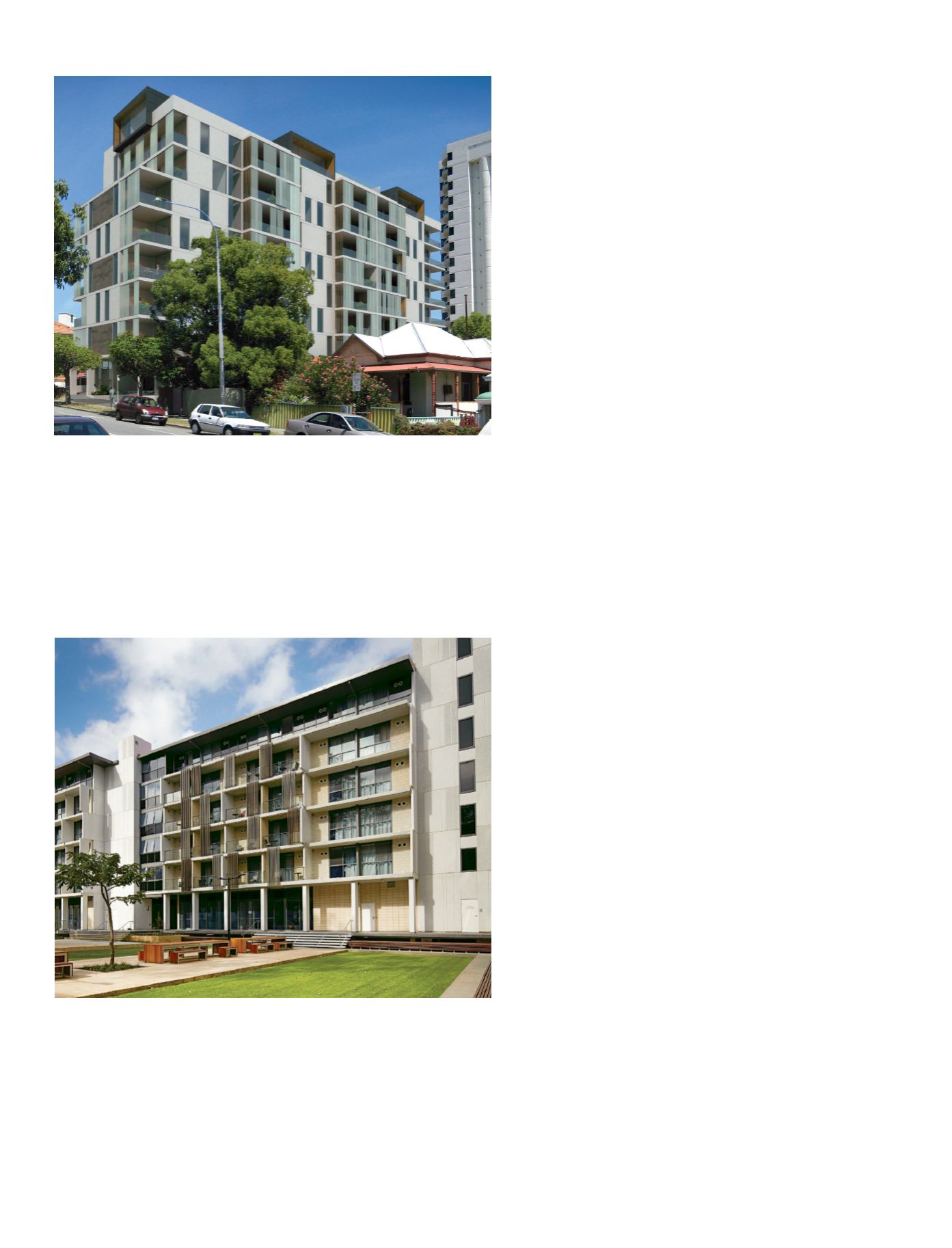

About six kilometres downstream on the Swan River is the

University of Western Australia.The award-winning

University Hall project created apartment-style

accommodation for over 500 undergraduate and

post-graduate students in three buildings over three, five

and seven levels.

Again this project made use of the efficiencies of both

precast walling and the Austral Deck precast flooring

system.The project was designed by HASSELL and

constructed by Probuild.

Project:

University Hall

Location:

Thomas Street, Crawley WA

Function:

Student accommodation

Owner:

University of Western Australia

Architect:

HASSELL

Structural engineer:

Robert Bird Group

Builder:

Probuild

Photography:

Douglas Mark Black

Project:

Vibe Apartments

Location:

35 Wellington Street, East Perth WA

Function:

Apartment building

Developer:

Vibe on Wellington

Architect:

Campion Design Group (design),

Aztec Architects (administration)

Structural engineer:

Peritas Group

Builder:

Ren Construction