94

|

design

mag

Even the carbon expended in transporting the bricks to the customer

– anywhere in the world! – is fully offset.All Daniel Robertson bricks are

certified Carbon Neutral from raw material excavation through to

delivery of the finished products to the work site.

This is on top of the life-cycle advantages of clay bricks such as their

longevity, contribution to thermal mass, and the fact that they don’t

require expensive, energy-hungry finishes such as paint or render to

maintain their good looks and durability.The Pullenvale home achieved

six stars on the BERS Pro housing energy rating scheme.

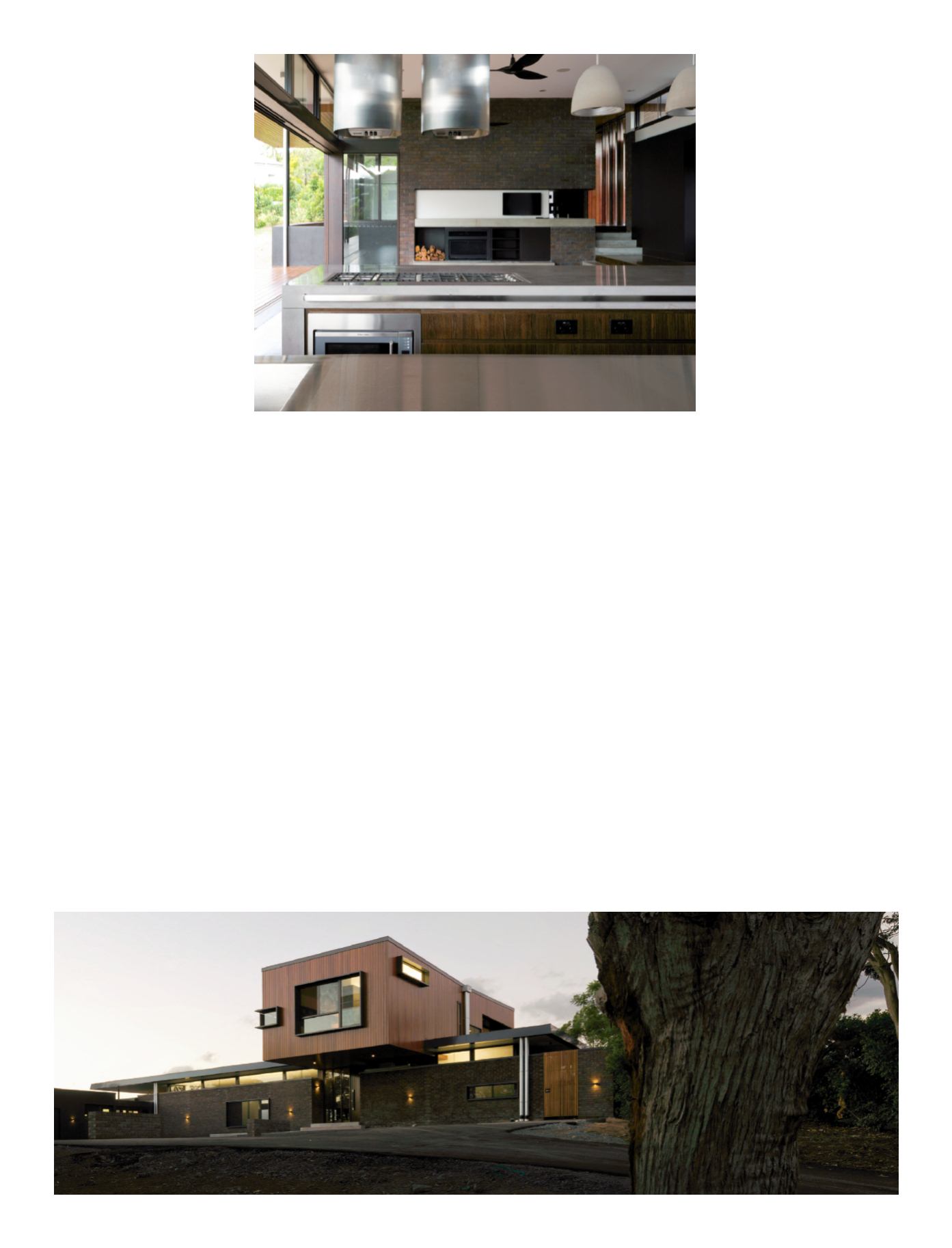

Building in a bushfire-prone area required a number of concessions.

The site was already largely clear, minimising the tree removal required

to create a buffer zone.The degree of threat varies from highest near

the garage to lowest on the long northern elevation. Fire-resistant timber

species such as kwila and black butt were specified for window and

door frames, decks and to clad the lightweight upper level.

Brickwork is naturally immune to fire but the horizontal mortar joints were

required to be raked to minimise the formation of ledges that could

catch embers.Alternatively, the joints could have been finished as

ironed (half-round) or a weather-struck, which slopes upwards and

inwards from the edge of the lower brick.

Bushfire resistant. High thermal mass. Rich colours and textures. Long life.

Low maintenance.And now certified Carbon Neutral. Building with

Daniel Robertson bricks is the perfect answer for a sustainable,

attractive, liveable home ... wherever you are in Australia.

There’s a lot of steel in the structure, partly due to the lightweight upper

level which cantilevers off the underlying structure. It carries the master

bedroom, ensuite and one of the two studies in the house.

Steel posts support the superstructure including the considerable roof, a

hipped design with a two degree pitch that precluded trusses.These

supports rise through the brickwork cavity, performing double duty by

bracing the tall walls.This structural design also allows the highlight

windows lining the upper level of the southern wall to be recessed about

a metre from the outer edge of the brickwork.

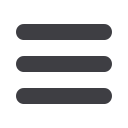

Not surprisingly, sustainability was to the fore.The site has 45,000 litres of

rainwater storage for topping up the swimming pool and as a firefighting

reserve. Extensive use is made of ceiling fans while air-conditioning is

limited to bedrooms and studies.There is no central heating, just the two

fireplaces and reverse cycle heating. Deep eaves shade the interior from

the high summer sun, while allowing the lower winter sun to penetrate

and warm the internal thermal mass of brickwork and concrete floor slab.

An unexpected bonus is that all Daniel Robertson bricks are now certified

as Carbon Neutral under the Australian Government’s National Carbon

Offset Standard.This is largely due to their manufacturing process which

uses waste sawdust as the primary firing material instead of natural gas.

Incremental improvements were also made to other aspects of the

manufacturing and associated processes, and the relatively small

residual CO2 emissions are offset by purchasing carbon credits that assist

in projects such as tree planting under the Forests Alive program

(forestsalive.com).