design

mag |

67

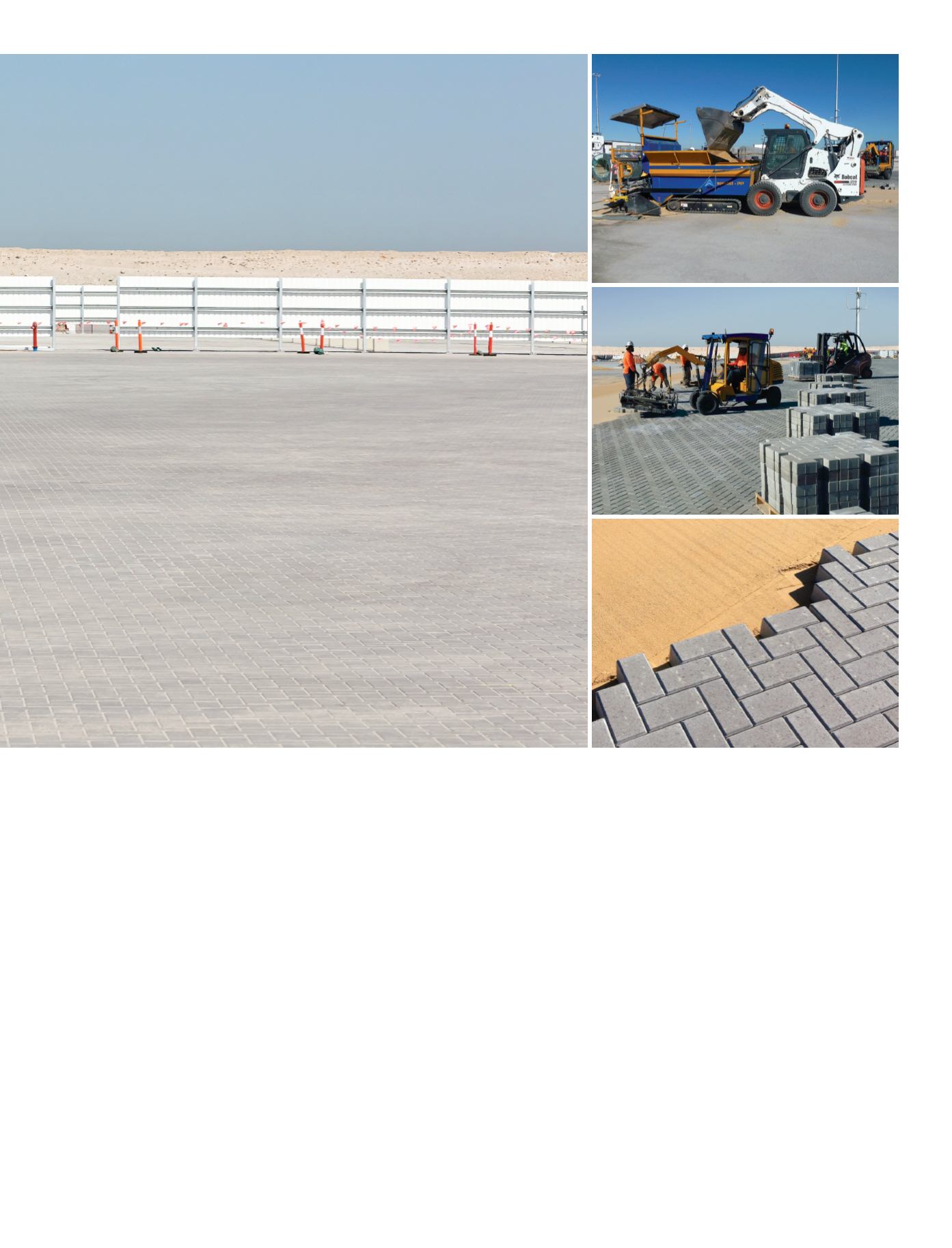

The cost effectiveness of concrete pavers has

been enhanced by the introduction of

mechanised laying.ACP Hardstand Solutions is

the market leader in heavy-duty segmental

pavement construction through the use of

specialised equipment such as the Probst

Powerplan PP screeding machine which lays a

thin bed of sand to support the pavers. Using

laser guidance, the machine deposits the sand

and screeds it to the finished level with a speed

and precision that would be unattainable using

manual methods.

The pavers are laid using a vacuum

attachment on a skid-steer loader that lifts a

layer of pavers from a pallet and deposits them

in the pattern. For this project the pavers were

laid at an average of 1500 square metres per

day, peaking at about 2000 square metres.

The pavers are cast in special moulds at the

Austral Masonry factory, arranged in the final

laying pattern.The pattern chosen for Port

Botany was 90 degree herringbone, which has

strong interlocking characteristics.

“Pavers that are 80 to 100 millimetres thick and

laid in a 90 degree or 45 degree herringbone

patterns are the only ones we would use on

heavily-trafficked areas,” explains Ryan Daly,

ACP’s contracts manager.

The pavement is then compacted using a

hydraulically-driven vibrating triple-plate

compactor attached to a skid-steer loader.“The

initial compaction is made as soon as a section

of pavers is laid and then two further

compactions are applied before the end of the

day,” says Ryan. Compaction drives some of the

sand up into the joint between the pavers,

enhancing their interlock.

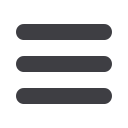

The result is a smooth, massively strong

pavement that will readily handle the loads at a

container terminal.“One hundred tonne

Caterpillar D11 bulldozers are driven over one

ACP installation and it’s not rutting at all,” Ryan

reports.“You are not really going to get anything

heavier than that!”

This was the first time ACP has used Austral

Masonry’s Techpave

™

100 heavy-duty

concrete pavers ... and Ryan Daly is

impressed.“We didn’t have any problems

with size variation or anything like that.”

As well as ports, heavy-duty concrete pavers

are also finding a ready market in airports,

car parks, intermodal terminals, mining sites,

and more.

“From my point of view, and I’ve been in the

industry for 12 years, these Techpave 100

pavers are the best product we have used,”

Ryan Daly concludes.

The extensive pavement will soon be

carrying massive loads of containers

and container handling equipment.

The mechanised laying process

includes a machine to spread and

precision screed the bedding sand

and mechanically position the

pavers. Once compacted, the final

pavement can handle considerable

loads and is easily maintained