66

|

design

mag

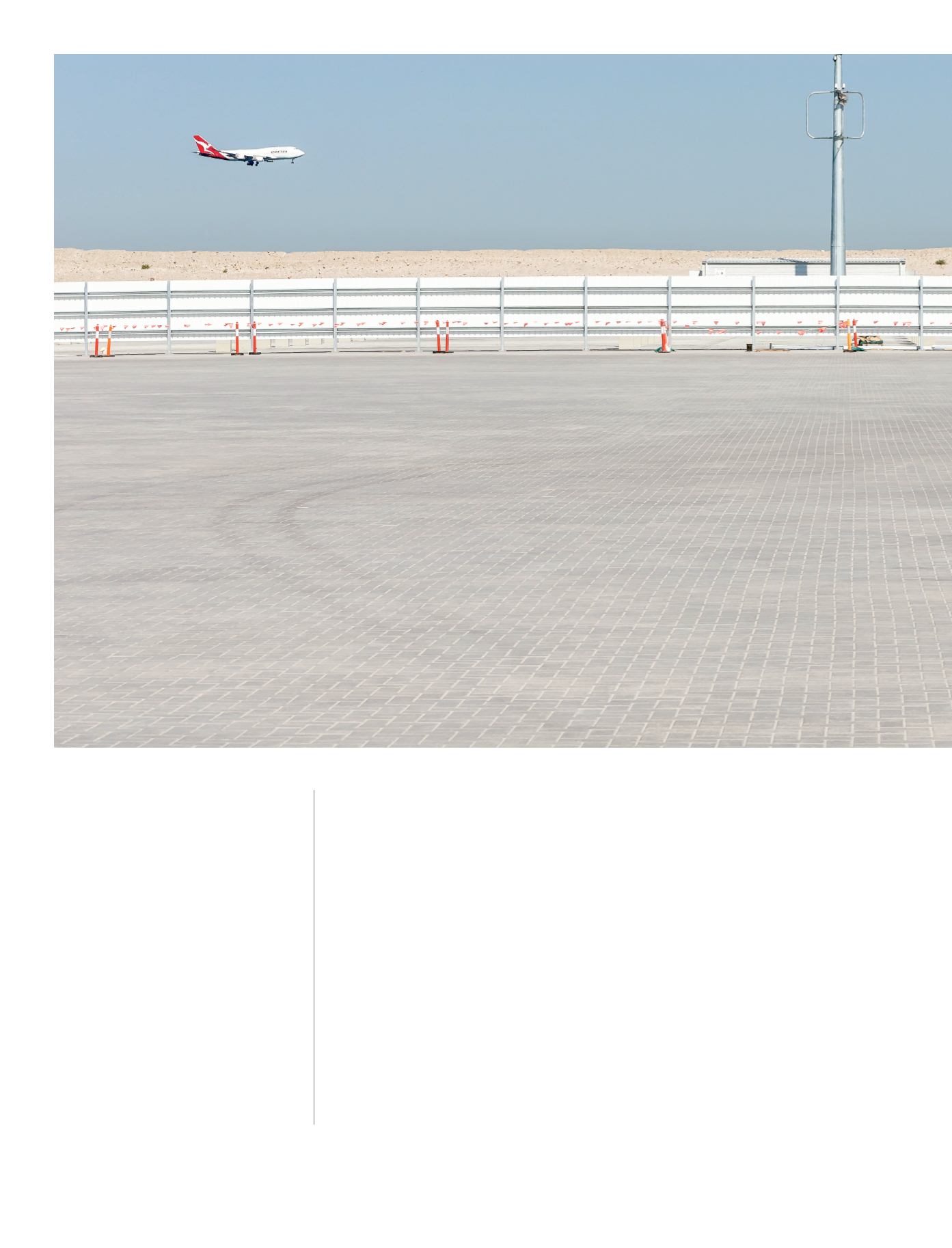

The humble shipping container has

revolutionised international trade, lowering

costs and simplifying handling and transport.

Ports across the world are taking this to the

next level by automating the movement of

containers off ships, and into and out of

the port.

Patrick’s Container Terminal at Sydney’s Port

Botany has recently been extended to cater for

additional traffic and new straddle carriers that

will operate unmanned 24/7 using guidance

technology.

Austral Masonry’s Techpave 100 concrete

pavers from the Zetech range, were selected to

cover the 60,000 square metres of the Port

Botany extension.They were laid by Perth-based

ACP Hardstands using specialised equipment

that speeds up the construction process and

lowers costs.

But first some background. Containers are

heavy, even more so when they are stacked

three high as they are for this site. (On some

sites they reach up to five or more.)

Each container stands on four small feet,

multiplying the effective loading. Patrick’s new

straddle carriers are no lightweights either, each

weighing 65 tonnes unladen.

Conventional asphalt paving cannot reliably

carry these loads and mass concrete is

expensive to construct and difficult to maintain

in the event of wear or localised failure.Asphalt

is also susceptible to damage by fuel or oil

spillages.

In contrast, heavy duty concrete pavers are

economical, hard wearing, easy to maintain,

and highly resistant to being displaced by

horizontal or vertical forces. In the event of

damage, individual pavers can be easily

removed and replaced or reinstated.The pavers

are laid on a sand bed about 20mm thick.

Project:

Patrick’s Container Terminal

Location:

Port Botany NSW

Head contractor:

Fulton Hogan

Paving contractor:

ACP Hardstand

Solutions

Featured product:

Austral Masonry

Zetech

™

Techpave

™

100 heavy duty

concrete pavers, natural colour

Photography:

Alex Mayes, production

photos courtesy ACP Hardstand Solutions