54

|

design

mag

“It was a true collaboration,” Karen says.“We

brought our technical skill and then Greg

really took the role of the artist, creating the joy

in the building.”

The building has three levels. Emma’s parents

have a self-contained two-bedroom

apartment on the ground floor, with its own

street access.The upper floors, Greg, Emma

and Archie’s domain, are accessed from the

lane.The middle level has two bedrooms and

two bathrooms while the top floor has an

open plan kitchen, diner and living area.A

glorious, custom-made, electric-blue spiral

staircase connects the levels.

With Greg as the owner/builder it’s no surprise

that the walling is brick. Even less surprising, it

is cavity brickwork, with foilboard insulating the

space between the two brick skins.

Greg carried out the bricklaying, assisted by

his former apprentice master, John Agnoletti.

“John’s an old school Italian guy, he’s really

cool,” says Greg, who all these years later is still

in awe of his old boss. Completing the team

was Tristan Walker, who was Greg’s former

apprentice.Three generations of bricklayers,

three mates.

The internal brick face is simply painted white;

no plasterboard please! The real treat is the

three storey wall on the laneway, which is a

demonstration of Greg’s artistic abilities in its

colour, texture and functionality.

But first, we need to go back to Greg’s high

school days when he finished a small clay pot

with a blue glaze. It’s still proudly displayed

and this striking glaze became the basis of his

colour choice for the laneway brickwork.

No one makes bricks that colour so Greg

determined to glaze them himself, all 10,500 of

them. By hand.That’s quite a challenge so he

went to Richard West at The Brick Studio in

Richmond who offered Austral Bricks’ technical

assistance and access to production facilities.

But the hard graft of hand-glazing thousands

of individual bricks was down to Greg.

illustration hidden in a shallow recess behind

a wired glass door. Finely fluted edges on the

concrete slabs. Concreter’s formwork

repurposed to make trusses.A workbench

curved around the spiral staircase at the

second level; the bench top was Greg’s

father’s.A massive riveted iron beam (very

Steam Age) rescued from the demolished

Myer Lonsdale Street store.

(You will need to watch the Grand Designs

Australia episode to learn Greg’s unique

method of patinating a copper downpipe.)

So how was the Grand Designs experience? “It

was just like blokes talking about a house,”

says Greg.“They were really respectful and just

into it as well. Peter (Maddison) really liked it

because it was all handmade.” He believes

that as an architect, Maddison had difficulty in

coming to terms with the lack of detailed

plans, but he eventually “really liked the fact

that it was all in my head.”

From the street, this unique project presents

almost as a single-fronted cottage. Inside it

looks like a renovated warehouse, an

assumption often made by visitors. For Greg it’s

a “twenty-first century interpretation of the Arts

and Crafts architectural style that flourished in

the late 1800s.”

To this observer it has more of a grunge

aesthetic, a homage to the Industrial Age of

the 18th and 19th century with its tiles, wired

glass, glazes, riveted beams, polished

concrete, steel and timber. Karen Alcock

describes it as “flamboyant” and admits that

Greg “probably pushed it a bit further than we

anticipated in some areas. I think it is always

interesting seeing people who are coming

from a different design perspective and seeing

what they come up with.”

For Greg Saunders it is more simple.“To me this

is like a homage to my friends who believed in

me,” he says modestly. Greg includes his

in-laws in that tribute but more especially his

partner, Emma, whom he describes as an “all

round good chick. None of this would have

happened but for her.”

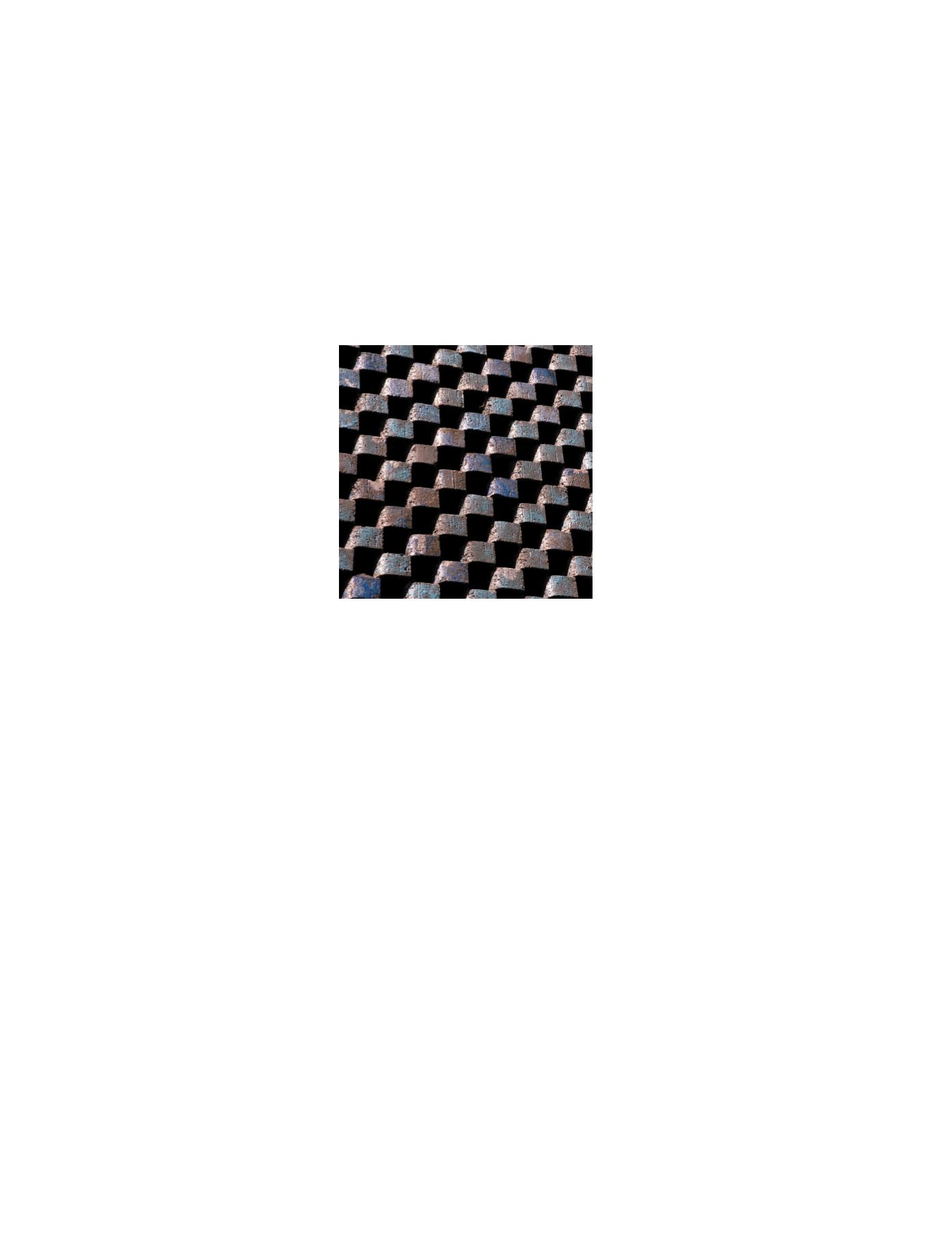

Working with Austral’s technical staff, three

glaze formulas were devised after a lot of trial

and error, and a process developed.A kiln car,

a giant trolley used to transport bricks through

the brick factory on Melbourne’s northern

fringe, was stacked with thousands of green

(unfired) bricks.

These were unloaded one at a time by Greg.

Each brick face was brushed with a thick

glue-like liquid and a small baker’s sieve

sprinkled the glazing powders over the face.

The more powder, the more intense the colour.

The kitchen and dining area (and

even a small plunge pool, not

shown) are at one end of the top

storey, while the living area

occupies the far end.All 10,500

face bricks were hand glazed and

refired. Operable windows behind

the perforated wall catch the

cooling afternoon breezes from

nearby Port Phillip Bay.

Each brick was then reloaded onto the kiln car

and the process repeated 10,499 times.The

bricks were then fired at over 1200 degrees

Celsius to a rock-like hardness.This high

temperature also triggered a chemical reaction

in the glaze, giving each brick face its distinctive,

original colouring and pattern.

“For such a massive company to be into such a

little project like this, it’s just cool,” says Greg.“I

owe Richard West and the Austral Bricks

technical staff so much.They were so good to us.”

Even this glazed brickwork is not quite straight-

up-and-down. On the two storeys above the

entry off the laneway, the architect had originally

proposed openable windows to catch the

breeze off nearby Port Phillip Bay. Greg replaced

this with a breezewall made from hand-glazed

bullnose bricks laid on their side with operable

windows inside. Ingenious.

In the house there are more quirky yet practical

touches that could only come from Greg.A four

metre by one metre plunge pool cantilevered

over the front (“replacing Archie’s old plastic

pool”).A life-size Star Wars Stormtrooper